Scale Formation, Prevention, Removal and Control

Scale Formation

There are several common scales which form on the walls of piping and equipment by the precipitation of dissolved ions.

Scale formation is the deposition of sparingly soluble inorganic salts from aqueous solutions. Another type of scale contains metal ions in which the anions are organic carboxylates. Scale can deposit on almost any surface, so once a scale layer is first formed, it will continue to get thicker unless treated. They can deposit on equipment in the well, such as electric submersible pumps or sliding sleeves, causing them to malfunction. Scale can occur anywhere along the production conduit, narrowing the

internal diameter and blocking flow, and finally, the scale can form in the processing facilities. Next to corrosion and gas hydrates, scale is probably one of the three biggest water-related production problems and needs to be anticipated in advance to determine the best treatment strategy. For some fields, scale control can be the single biggest operational cost.

Common Scales

Solubility can be defined as the limiting amount of a material that can be dissolved in a solvent under a given set of conditions. Nearly all salts of sodium and potassium have high solubility in water. Sulfate salts of calcium, barium, and strontium, and the carbonate salt of calcium have limited solubility. Calcium carbonate and sulfate scales are quite common and can be precipitated from many surface and well waters, including seawater and aquifer waters. Barium sulfate rolex replica scale is a serious problem in some producing wells.

Heat losses curve because the scale forming

Types of scale

The most common scales encountered in the oil industry in order of prevalence are

- Calcium carbonate (calcite and aragonite)

- Sulfate salts of calcium (gypsum), strontium (celestite), and barium (barite) radium may also be found in the lattice, especially that of barium sulfate

- Sulfide scales—iron(II), zinc, and lead(II) salts are the most common

- Sodium chloride (halite)

Factors Influencing Scale Formation

The following major factors influence scale formation:

- Concentration of scale forming ions

- pH

- Temperature

- Pressure

- Total dissolved solids

Scale Prevention

Several options that are available for preventing scale formation are as follows

- Dilution

- pH control

- Removal of scale forming ions

- Scale control chemicals

- Non chemical scale control devices

Dilution

In order to avoid scale formation, waters high in concentration of scale-forming ions can be diluted with water which does not contain the scale forming ions.

pH controle

In the example above, if the caustic had been neutralized with acid, it would have been compatible with the other water.

pH control is used to prevent scale formation in seawater used for injection. For example, at Qurayyah, the pH is strictly controlled by the addition of sulfur dioxide, which forms sulfurous and sulfuric acids in water.

Removal of scale forming ions

In order to prevent scale formation, the scale-forming ions can be removed from the water by precipitation softening and/or ion exchange softening. Produced waters are softened by these techniques in California before they are heated in steam generators and reinjected into heavy oil-producing formations.

Scale control chemicals

Several types of treatment chemicals can be used to prevent the formation of calcium sulfate and carbonate scales. Some phosphonates, polyphosphates, and water-soluble polymers and copolymers act as crystal distorters and slow the growth of scale-forming crystals. Other polymers can be used to disperse small crystals in the water so that they do not form scale on the surfaces of equipment and piping.

Non chemicals scale controle

It’s a device that is claimed to prevent scale formation by operating on some vague magnetic, catalytic, or electrostatic phenomena. There are always theories to support the claimed mechanism by which these devices work. On close examination, these theories are not substantiated by any valid scientific principle. Laboratory or field trials, should they exist, are poorly controlled and rarely well documented. Based on available information, the use of devices that operate on these phenomena to control scale formation is not recommended.

Deposits management strategy

The specific deposit management activities that are chosen by a utility can include a

combination of any or all of the available deposit removal services that are available

from vendors.

The goals that often provide a basis for the strategy include :

- Maintain or maximize heat transfer (plant output)

- Reduce risk of secondary side corrosion

- Reduce risk of unwanted thermal hydraulic issues

- Reduce the potential for tube wear and vibration cause by changes in flow patterns

Mechanical cleaning

- Water jet lancing is a common cleaning processes . Also known as “sludge lancing

- Advanced in-bundle water jet cleaning

- Full bundle mechanical cleaning

- Pressure pulse cleaning

- Ultrasonic energy cleaning

Chemical cleaning

Chemical cleaning is a very effective means of deposit removal, historically resulting in the dissolution and removal of deposits.

Two different types of chemical cleanings also preferable in some cases.

- On-line chemical cleaning

- Off-line chemical cleaning

Cumulative no. of chemical cleaning performance world wide

Chemical cleaner

Inhibited acids, converters, chelants, caustic, and hydrocarbon solvents are available for removing scales and deposits of corrosion products. The temperature and contact time greatly affect the speed and effectiveness of cleanings.

Inhibited acids are commonly used to remove calcium carbonate deposits. Hydrochloric acid effectively dissolves the scale and converts carbonate to carbon dioxide gas. Due to the corrosive nature of hydrochloric acid and the fact that it will generate deadly hydrogen sulfide gas if sulfides are present, cleaning should only be performed by experienced personnel. Chelants are compounds that dissolve hardness ions by preferentially binding to them. They are less corrosive than acid but are less efficient and expensive; consequently, they are used less frequently.

Chemical cleaning solvent chemistries

Several different chemistries are required to clean a HE completely. The different chemistries dissolve deposits in different areas or different types of deposits. One chemistry is utilized to remove the bulk deposits, another chemistry is utilized to remove the deposits in the crevice region, and finally, different chemistry is utilized to remove copper deposits. This report will discuss all of these chemistries and how they remove the targeted deposits.

All of the chemical steps are not required for each HE cleaning. The process engineer must identify the goal of the cleaning and design the cleaning steps in order to achieve the goal.

Performance & control

Approach condenser

This value is easy to determine if water and process temperatures are measured for an exchanger. Approach temperature can be used as a first step in monitoring performance of exchangers where condensation does not occur or in process condensers where the condensate is not cooled below the condensation temperature.

The simplest definition of approach temperature is the difference between the process outlet temperature and the cooling water inlet temperature.

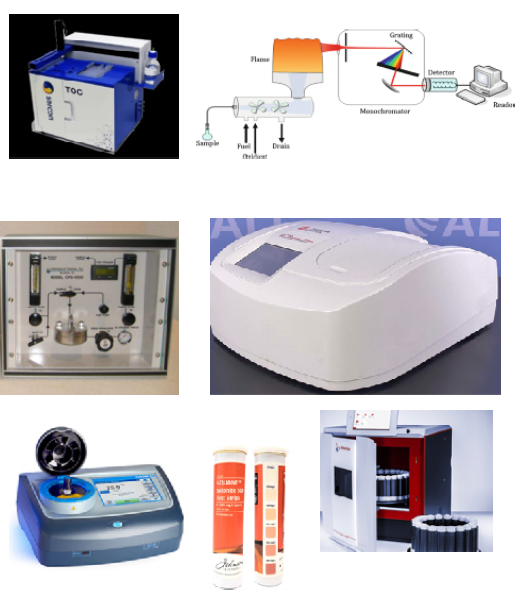

The most common types of laboratory tests carried out for new scale inhibitor applications include the following:

- Static bottle tests

- Tube-blocking test

- Compatibility tests

- Thermal ageing (in solution or on rock)

- Static adsorption tests

- Dynamic adsorption tests—core flooding, including permeability changes

References

SG for nuclear power plant, Scale control, Lab 20704 Saudi Aramco DeskTop

Standards.

Copyright © Raduis AK, All Right Reserved.